Project info

- Passenger vehicles and service

11 Aug 2018

Rakhmat Fayziy Street, 8

Shedevr Garden Restaurant

09:00 - 18:00

+998 99 310 0990

+998 99 322 0990

About project:

Engine repair shop is a specialized workshop for the repair and restoration of any internal combustion engines.

Our mechanical workshop carries out repairs of foreign and domestic engines with a quality guarantee, and the Avtoritet Avtomechanics specialists have extensive experience in restoring the performance of various ICE models.

Having equipped the workshop with the most modern equipment and having assembled a team of experienced professionals, we carry out repairs, the quality of which is comparable to a new part. Our machines allow processing parts with the minimum possible metal removal, which in turn makes it possible to increase the number of permissible repairs of expensive engine elements.

Services:

Cylinder block, as well as cylinders – motor vehicles, compressors, etc.

- Washing;

- Diagnostics, including alignment of beds of cardan shaft and distribution shaft;

- Pressing;

- Boring to size;

- Honing;

- Casing (under pressure or using a temperature difference);

- Casing of cast iron and aluminum blocks;

- Milling of the mating plane;

- Grinding of the mating plane;

- Restoration of the geometry of the crankshaft bed (boring - restoration of the bed).

Cylinder head:

- Washing;

- Diagnostics;

- Pressing;

- Grinding the mating plane;

- Milling of the mating plane;

- Repair and replacement of valve seats;

- Repair (restoration) and replacement of valves;

- Repair and replacement of valve guides with the possibility of restoring cast guides of imported cars using bronze valve guides;

- Adjustment of clearances for internal combustion engines in which valve pushers are installed in place of hydraulic compensators;

- Cylinder head repair on turnkey basis;

- Restoring bed of distribution shaft - as well as regrinding necks of distribution shaft.

Crankshaft:

- Washing;

- Diagnostics;

- Grinding;

- Polishing using a special polishing tape and a specialized polishing machine;

- Dynamic balancing;

- Manufacturing of crankshafts inserts of non-standard dimensions;

- Repair of axial backlash of crankshaft (half ring);

- Grinding of the crankshaft journals using the measurement technology - metrological measurements of each bed separately with the installation of a sleeve-insert bearing, which is important - when using non-original liners, or to obtain high result.

Repair of connecting rods:

- Diagnostics of the connecting rod for twisting and bending;

- Measurement of the conformity of the geometric dimensions of the connecting rod to the factory parameters (center-to-center distance, diameters of connecting rod small end, connecting rod big end, diameter of a pin);

- Replacement of connecting rod big bushing (CRB);

- Boring of the CRV sleeve to size;

- Restoration of the lower connecting rod head;

- Correction of the center-to-center distance;

- Re-pressing of the piston pins (using a temperature difference or as required by the manufacturer).

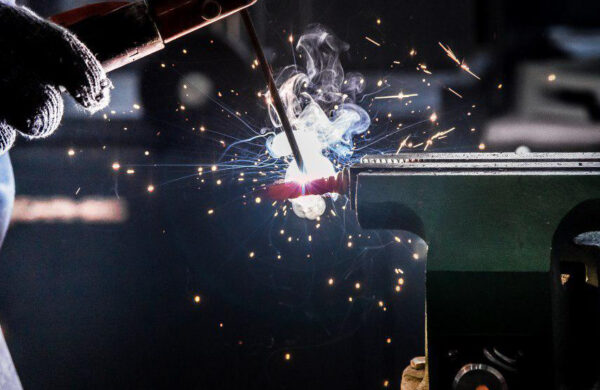

Welding works:

- Welding of parts made of cast iron and its alloys

- Argon welding of parts made of aluminum and its alloys

- Welding of other non-ferrous metals, as well as stainless steel

- Welding of radiators, fuel tanks etc.

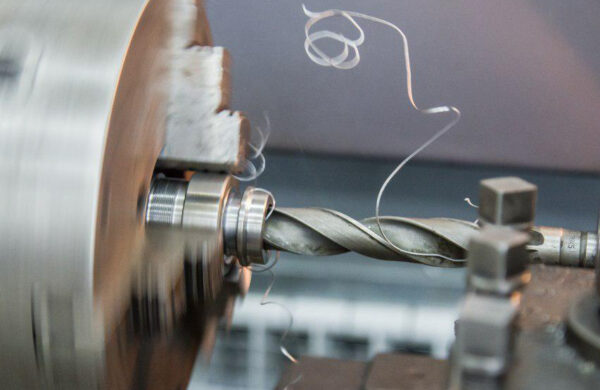

Additional services:

- Turning works;

- Milling work;

- Grinding work;

- Washing of internal combustion engine parts and other units using jet and submersible washing machines.